Air Cannons

Hurricane Air Cannon

Martin® Hurricane Air Cannon / Air Blaster Systems improve the flow of bulk materials and prevent outages due to discharge blockages, buildups and ratholes. The Hurricane features a new valve concept that provides more force, uses less air and simplifies installation and maintenance.

Multi Valve Air Cannon

Using a single air tank with up to five independent valves, the Martin® Multi Valve Air Cannon / Air Blaster improves flow at five discharge points.

Retractable Nozzle

The Martin® Air Cannon / Air Blaster Retractable Nozzle extends service life in preheater towers and high temperature / high dust applications by pulling the discharge inside the vessel.

Tornado Air Cannon

The Martin® Tornado Air Cannon produces better material flow with greater force, faster cycling, and improved safety. The Martin® Tornado Air Cannon fires when the exhaust valve opens in response to a positive surge of air sent by a tripped solenoid valve.

Typhoon Air Cannon

The Martin® Typhoon Air Cannon features a hybrid valve concept that provides more force, uses less air, and simplifies maintenance in challenging applications with limited budgets.

Belt Support

EVO® Slider Cradle

The EVO® Slider Cradle utilizes low friction UHMW bars to support the belt at the outside of the load-carrying area. This stabilizes the belt line, eliminating the sag and bounce that spill material and reducing the risk of catching lumps that can abrade the belt surface.

Slider Cradle

Installed under the skirtboard of a transfer point, Martin® Slider Cradles support the edges of the belt to eliminate sag. These cradles prevent transfer point spillage by stabilizing the belt’s path and allow the effective sealing of the belt edge.

CYA Doors / Guarding

Inspection Door

Martin® dust-tight steel inspection door allows inspection and access in chutes and other enclosures for belt cleaner maintenance or other service requirements.

Conveyor Guards

To improve worker safety, mesh panel guards conform to OSHA / MSHA standards and prevent worker exposure to conveyor nip points and pinch point hazards.

Impact Beds

Impact Cradle LD

Installed under the belt conveyor loading zone, Martin® Impact Cradles absorb the force of falling material to prevent damage to the belt and structure and to help eliminate spillage.

Impact Cradle MD

Installed under the belt conveyor loading zone, Martin® Impact Cradles absorb the force of falling material to prevent damage to the belt and structure and to help eliminate spillage.

Primary Belt Cleaners

Compact Cleaner

Martin’s smallest primary cleaner fits in tight quarters for effective belt cleaning / belt scraping in applications where pre-cleaner space is limited.

PV Cleaner

Formerly PIT VIPER Pre-cleaner, this primary cleaner / belt scraper uses a one-piece urethane blade for effective belt cleaning on aggregate industry conveyors.

QC1™ Cleaner HD

Heavy-duty one-piece curved urethane blade combines sturdy primary belt cleaning performance with one-pin blade replacement to out-perform competitor's belt scrapers.

QC1™ Cleaner HD Max

QC1™ Cleaner HD Max

Sturdy urethane blade of this pre-cleaner / primary cleaner provides effective removal of material from belt conveyors handling coal, ore, or other bulk materials.

Sturdy urethane blade of this pre-cleaner / primary cleaner provides effective removal of material from belt conveyors handling coal, ore, or other bulk materials.

QC1™ Cleaner PD

Conveyor belt cleaner system features curved one-piece urethane blade for long belt scraper life, and quick-change blade replacement.

QC1™ Cleaner XHD

Martin® primary conveyor belt cleaners and belt scrapers are installed in the pre-cleaner position on the face of the head pulley. These pre-cleaners use low pressure to remove 75 to 90 percent of the carryback material.

SHD 1200 Series Cleaner

Super Heavy-Duty (SHD) Pre-Cleaner uses massive urethane blade as effective primary conveyor belt cleaner / belt scraper on wide, fast, high-speed conveyors with head pulley larger than 48 inches (1200 mm).

SHD 600 Series Cleaner

Installed in pre-cleaner position, the rugged Super Heavy-Duty primary cleaner serves as an effective belt scraper for tough, mine-grade belt cleaning on conveyor pulleys smaller than 48 inches (1200 mm).

ZHD Cleaner

Martin® ZHD belt cleaner / belt scraper combines urethane blade segments to form effective primary cleaner in pre-cleaner position on face of head pulley.

Secondary Belt Cleaners

DT2 Inline Cleaner

Martin® DT2 Inline secondary conveyor belt cleaning / belt scraping system fits in narrow spaces. Slide-in / slide-out blade assembly allows quick belt cleaner service, minimizing downtime.

DT2 Inline Cleaner XHD

The Martin® DT2 Inline Cleaner XHD secondary conveyor belt scraper features rugged blades installed on a track that slides into cleaning position on a rigid steel mandrel.

Durt Hawg® DH2 Cleaner

The Martin Durt Hawg® DH2 Secondary Belt Cleaner / Belt Scraper provides improved cleaning efficiency with a high-volume blade for longer life and a sturdy mainframe that withstands tough conditions. Requires only a hammer to mount steel cleaning blades.

H2O Cleaner

Martin® H2O Belt Cleaner’s urethane secondary cleaner blade acts as a belt wiper to squeegee the conveyor belt and leave a clean, dry surface.

O2 Cleaner

The Martin® O2 secondary conveyor belt cleaner holds tungsten carbide blade tips at "paint-scraper" angle for maximum cleaning of conveyor belt carryback. Material slides off blade shields without buildup and flexing blade holders deflect tip to allow splice passage.

SAF2™ Cleaner

Martin® SAF2™ secondary conveyor belt cleaner features resilient urethane blades that “stand tall” to maintain effective belt cleaning pressure even as blade wears.

SQC2S™ Cleaner

The Martin® SQC2S™ Secondary Conveyor Belt Cleaner incorporates individually-cushioned tungsten carbide blades for effective conveyor belt cleaning without risk to belt, splice, or blade.

Skirt Rubber and Systems

ApronSeal™ Double Skirting

Features and Benefits: Provides effective sealing on higher speed belt.Offers dual life - dual sealing system in a one-piece construction. EPDM 70 durometer rubber composite offers good and low-abrasion index characteristics.

EVO® External Wear Liner

Allows precision alignment of steel panels to avoid points that entrap material and damage the belt.Makes it easier to inspect the liner and it is easier to replace that liner when required - both without confined space entry.

V-Plows and Vibration

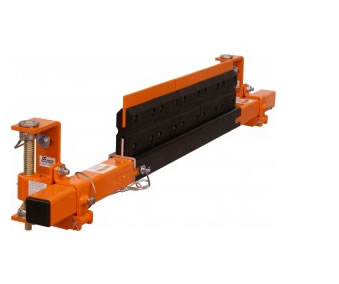

Torsion VPlow

The Martin® Torsion VPlow is mounted with a unique suspension that allows the plow to rise and fall with fluctations in belt tension and travel. This makes it self-adjusting for effective cleaning in all stages of blade wear.

Cougar® NHD Hydraulic Vibrator

Built from high-strength ductile iron for maximum durability. Efficient motor design for minimal power consumption. Adjustable eccentric weights. Low maintenance. Designed to create more force per size/weight. Variable speed. Continuous duty

Replacement Vibrators / Motors for Derrick® Vibrator

Martin® Screen Vibrators / Motors are explosion proof vibrators for vibrating screens / dewatering screens and serve as direct replacement motors for Derrick® Screen Vibrators.

Hydraulic Screen Vibrator

This industrial vibrator provides hydraulic vibration for efficient material separation on screen tables or compaction tables. The Martin® Hydraulic Screen Vibrator provides efficient power to sort or separate material.